The effects of rice husk biochar and its silicon content on corn (Zea mays L.) growth

Biochar preparation and characterization

Four rice husk biochars were used in this study; biochar from International Rice Research Institute (IRRI), biochar from Industrial Technology Research Institute (ITRI), Shui-biochar from Shui-known Company and biochar from National Pingtung University of Science and Technology (NPUST).

IRRI biochar was prepared by the International Rice Research Institute in Philippines by drum method. This process takes about 4 to 8 hours depending on the amount of rice husk to be processed. ITRI biochar was prepared by the Industrial Technology Research Institute in a specialized biochar reactor; Shui-known biochar was obtained from Shui-Known Company made in fast pyrolysis reactor. NPUST biochar was produced at National Pingtung University of Science and Technology in a laboratory scale reactor with a process period of 1 hour (see table 1).

IRRI

ITRI

Experimental design

A net house experiment was set up to study the effect of rice husk biochar on corn germination and growth. The four rice husk biochars mentioned above were used in this study.

The treatments were prepared as follows:

The treatments were prepared as follows:

Several analyses including scanning electron microscopy (SEM) equipped with an energy dispersion X-ray spectroscopy (EDX), Fourier transform infrared spectroscopy (FT-IR), volatile matter (VM), electrical conductivity (EC), water holding capacity (WHC), and heavy metal analysis (ICP), were used to characterize the biochars properties.

Source: http://www.xos.com/techniques/sem/

SEM-EDX

FTIR

Source: http://webb.cm.utexas.edu/research/research_SEI.html

VM

EC

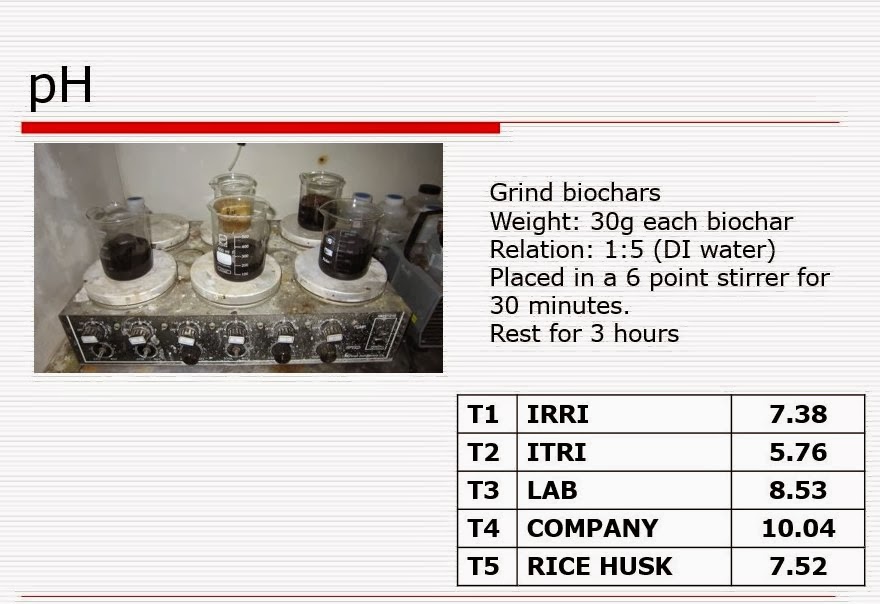

Biochar samples were dried in a precision oven at 35ºC after where ground and passed through a 2mm sieve (10 mesh), we used 20 grams of biochar in 20 ml distilled water. A pH meter was used to measure the pH levels in the prepared solution. All biochars had a higher pH than their corresponding crop husks, indicating the higher alkalinity of biochar compared with the husks and suggesting the concentrating of alkaline substances in crop straws during pyrolysis.

These seven treatments were arranged in fully randomized design with 4 replications, each one of 10 plants in separated pots.

The amount of soil amendment applied (45g) was calculated based on the surface area of the plastic pot used ( 4.5 x 5.0 cm), and the amendments were mixed to a 5 cm depth, after preparation they were placed in the net house and watered every two days. 10 plants (pots) were grouped together to make one plot for a total of 7 treatments x 4 replications x 10 plants (pots)/plot = total of 280 plants (or pots). The germination and growth of corn plants was performed for 15 days.

Rice husk biochar analysis

A HITACHI S-3000N scanning electron microscope equipped with an energy dispersion X-ray (EDX) was used to examine the morphology and silicon content of dried rice husk and biochar rice husk samples. The sample powder was sprinkled as a thin layer on an adhesive tape placed on the brass sample holder. Excess amount of the sample was removed using a small manual air blower. The adhered sample was then coated with gold powder using the sputtering device with the Ion Sputter E-1010 HITACHI, and then transferred into the JEOL sample chamber for the analysis. The accelerating voltage was set at 15-40 kV and 200,300 and 600 time magnification was selected.

FT-IR was used for the identification of the organic functional groups present for each biomass, especially carbons and -OH- groups.

Comments

Post a Comment