Biochar from charcoal production and recycling of agricultural and forestry wastes

Worldwide, 41 Mt of charcoal are produced annually for cooking and industrial purposes (Lehmann and Rondon, 2006). Most of this production is located in developing countries (40 Mt in 2002) rather than developed countries (1 Mt), with Africa being the highest producer (21 Mt) in comparison to South America (14 Mt) and Asia (4 Mt). Charcoal production is often detrimental to the environment, as it leads to deforestation and air pollution. Yet, most developing countries have few alternatives to charcoal production for household fuel. However, significant improvements are possible with viable alternatives as far as wood production, charcoal production with respect to human health and use of charcoal waste is concerned.

Additionally, it has been argued that use of charcoal as a fuel replacing wood leads to lower levels of household indoor pollution and an associated reduction in mortality (Lehmann and Rondon, 2006). For industrial purposes and in large-scale commercial operations, options for clean and efficient charcoal production exist.

Source: Retort Charcoal Kilns, Uganda (https://www.facebook.com/media/set/?set=a.470236356332073.105146.121151734573872&type=1)

Charcoal wastes may however, be of regional importance where small-scale producers dominate the market such as in most parts of Africa, in rural areas in South America and Asia. Charcoal waste can be applied as bio-char to agricultural soils (including the fields where the trees are grown for charcoal production) and turned into a valuable resource for improving crop yields on acid and infertile tropical soils where nutrient resources are scarce (Lehmann and Rondon , 2006).

Recycling of agricultural and forestry wastes

In many agricultural and forestry production systems, waste is produced in significant amounts from crop residues such as (i) forest residues (logging residues, dead wood, excess saplings, pole trees); (ii) mill residues (lumber, pulp, veneers); (iii) field crop residues; or, (iv) urban wastes (yard trimmings, site clearing, pallets, wood packaging). Other industry and municipal residues could potentially be a suitable and quantitatively important source of bio-char.

Many of the forestry and agricultural residues can be used to produce bio-char and applied to agricultural soil both to sequester C and to improve the production potential of crops. In many cases, these waste materials have little value and their disposal incurs costs. Today large amounts (more than 50% of total available residues in the U.S.) can be acquired for less than $ 30 per ton of biomass. Other opportunities exist to utilize residues from pulp mills, from eucalyptus plantations to combat salinization and obtain eucalyptus oil, or as an alternative to garbage incineration.

BIOCHAR, WHEN USED FOR COOKING, IS MADE OUT OF ORGANIC HOUSEHOLD AND CROP WASTE. Source: http://stewards.snre.umich.edu/article/starting

Not all agricultural waste materials are suitable to produce bio-char, including many field or vegetable crop residues with the notable exception of rice husks, which has high concentrations of silica entrapping C during combustion. Rice husks are typically regarded as a waste product, but can be used to sequester C by producing bio-char. Global rice paddy production is 0.589 Pg yr−1. From this, we calculate the sequestration potential to be 0.038 PgCyr−1 (calculated estimating 32% husk, 38% C concentration, and 53.5% conversion from husk C to bio-char C).

Other crop residues such as nutshells (e.g., groundnut, hazelnut, macadamia nut, walnut, chestnut, coconut) but also bagasse from sugar cane processing, olive or tobacco waste are suitable and are in some locations available in large quantities. (Lehmann and Rondon, 2006).

Bean and corn crop grown without biochar Photo Credit: David Guerena

Bean and corn crop grown with biochar Photo Credit: David Guerena

Benefits to the agricultural sector and waste management

The agricultural sector can benefit from biochar in two ways: soil improvement and animal and crop waste disposal. Soil improvement, and therefore increased productivity, can be the driver behind biochar production and use. Since 1980, field trials have been taking place around the world experimenting with the application of biochar types on specific soils.

Source: http://www.vermontbiochar.com/

The type of biochar varies with biomass type in many cases rice, wood or bark has been used and production parameters, such as the rate of pyrolysis and kiln size. In most of the studies, acidic soils have been the subject of research, and these have generally been in tropical or semi-tropical regions. Experiments have also employed differing treatments, applying relatively more or less biochar, with and without the use of other fertilizers.

Results of trials have ranged from no increase in productivity (the case of banana plantations in Brazil) to as much as a 151 % increase in soybean yield in one project. In many cases, it was noted that soil acidity was reduced and mineral uptake increased, with residual effects sometimes lasting through to the following season or two. Research is still required into the use of biochar for pastures or tree plantations, and for soils in dry and/or temperate regions.

A second benefit of biochar production to the agricultural sector (and some industries, such as the paper industry) is the fact that it uses organic waste. Left to accumulate, animal and crop waste can contaminate ground and surface waters. Waste management practices are aimed at preventing such contamination, but they can become costly. Biochar presents an attractive alternative if the economic costs can be kept below those of waste management.

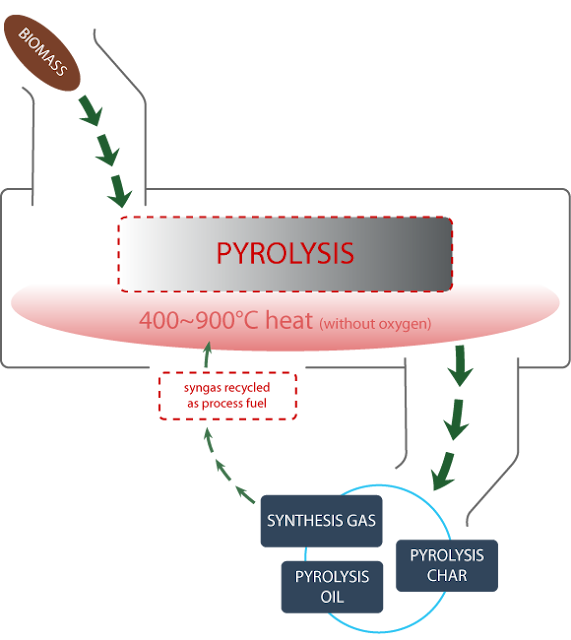

By accepting organic material as its input, the biochar production process transforms waste into a resource. The pyrolysis process reduces the weight and volume of the feedstock, and by operating at a temperature above 350°C, it removes potential pathogens that can be a problem if directly applied to soils. Green urban waste and waste from some industrial processes, such as paper milling, can also be used (Talberg, 2009).

For industrial purposes and in large-scale commercial operations, options for clean and efficient charcoal production exist. charcoal uses

ReplyDeleteWhat are the real tangible benefits of an agricultural B2B directory? In this vast world marketplace, it's important to connect buyers with the right kind of suppliers. In agriculture there are a diverse range of products available on the market. production animal

ReplyDeleteAgricultural tools and methodologies take the process of harvesting in upwards' direction. Right practice and operations in Deutz Parts Manual is very necessary for nation's development.

ReplyDeleteThis article will track the development of implementing HR, human resources, in the agriculture field. You will also learn a few reasons why it is so beneficial to do this. Mandi Bhav Today

ReplyDeleteWdiasufsump_go_1982 Stephanie Smith link

ReplyDeletetandvenmimo

OsucaMpulcgu Asia Ervin SideFX Houdini FX 19.5.303

ReplyDeleteAuto Clicker

Camtasia Studio

Microsoft Excel 2016

morrsubtjarwars